Converting Stainless Steel Fasteners from Screw Machine to Cold Headed for the Automotive & Electronics Industry

An international automotive company approached Jeffrey-Jae Company, Inc. for a cost saving alternative on a high-volume part. Jeffrey-Jae was able to convert these stainless steel fasteners from screw machine to cold headed for an automotive computer assembly application. Utilizing precision cold heading and a secondary shaving operation, Jeffrey-Jae was able to create a custom fastener with a head size of 5.7mm with the option of either a hex head or flat screwdriver slot. The 14.05mm long, .006oz steel fasteners were made from 302 stainless steel and had a tightest tolerance within .005". Each fastener came pre-assembled with a SEMS spring washer and featured a shank with a smaller than nominal thread diameter, allowing for easier assembly.

Most importantly, our processes not only saved the client 70% over screw machining but also gave them the option to create fasteners with any head type and thread up to 4.5" in length.

For more information on this project and other cold heading and secondary shaving operation projects please contact Jeffrey-Jae.

(click on thumbnail to enlarge)

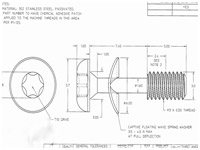

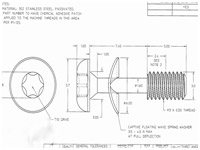

Shaved SEMS Screw Drawing

Shaved SEMS Screw Drawing

|

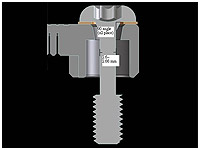

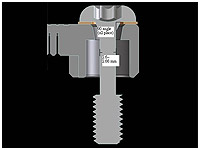

Shaved SEMS Screw

Shaved SEMS Screw

|

Shaved SEMS Application

Shaved SEMS Application

|

Converting Stainless Steel Fasteners from Screw Machine to Cold Headed Project Highlights Converting Stainless Steel Fasteners from Screw Machine to Cold Headed Project Highlights

| Product Name |

Cold Headed Stainless Steel Fastener |

| Product Description |

This was manufactured for an automotive computer assembly application. |

| Capabilities Applied/Processes |

Cold Heading & and Secondary Shaving Operation

- Form Fastener w/ Hex Head and Flat Screwdriver Slot

- Shave Shank in Secondary

- Assemble Lock Washer to Cold headed Blank

- Roll Threads (post washer assembly) to Ensure Washer Retention

- Passivate

- Apply Adhesive Patch to Threads

|

| Overall Part Dimensions |

Length: 14.05mm

Head Size: 5.7mm |

Shank: Ø1.60mm

Thread: M3 x .50 | |

| Tightest Tolerances |

+/- .005" |

| Finish |

Passivation |

| Material Used |

302 Stainless Steel |

| Features |

Pre-Assembled w/ SEMS Spring Washer

Shank has a Smaller Diameter Than The Nominal Diameter of Thread for Easy Assembly

Can be Manufactured w/ Many Different Features

- Any Head Type

- Any Thread

- Any Length up to 4.5"

70% Cost Savings over Screw Machining |

| Estimated Part Weight |

0.006 oz |

| Industry for Use |

Automotive / Electronics |

| Standards Met |

Customer supplied print, 2D CAD Drawing

ANSI IFI-141, "Zero Defects" |

| Delivery Location |

Munich, Germany |

Back to top |

Site created by Thomas Web Solutions

Site created by Thomas Web Solutions Site created by Thomas Web Solutions

Site created by Thomas Web Solutions

Call Us:

Call Us:

Print This Page

Print This Page